- Iterate

- Meet The Team

- Elemental Impact: Nordic Startups Revolutionizing Sustainable Use of the Air, Ocean and Earth

Elemental Impact: Nordic Startups Revolutionizing Sustainable Use of the Air, Ocean and Earth

Table of contents

To change the current trajectory of global warming and biodiversity loss, the world is in need of solid sustainable solutions that can be rapidly scaled to a global level.

To change the current trajectory of global warming and biodiversity loss, the world is in need of solid sustainable solutions that can be rapidly scaled to a global level. Startups using natural and renewable resources in new and innovative ways - with positive impact ingrained their business operations - are increasingly being acknowledged as powerful engines for change and sustainable growth.

Over the last two decades, the Nordic region has seen entrepreneurship gain significant popularity alongside a rapidly increasing awareness of environmental challenges. This dynamic has led to a new generation of sustainability problem-solving startups emerging from the region. From increasing the efficiency of solar panels with algae to turning atmospheric CO2 into food, this group of entrepreneurs see opportunities and possibilities where others see only issues.

The Org interviewed three up-and-coming companies that each demonstrate a powerful coupling of impact and profitability by utilizing the world’s renewable resources to their fullest potential.

Food Out of Thin Air

Solar Foods’ slogan sounds like sorcery - “food out of thin air” - but the Finnish tech company has in fact made that magic into reality. By using renewable electricity and air, Solar Foods has created a groundbreaking new way to produce natural protein. While the bioprocess to create this protein may be untraditional, it uses a fully natural fermentation process that is similar to the production of yeast. The result is a carbon-negative protein and a food production process that tackles several of Earth’s biggest challenges.

Solar Foods' first product is a natural protein called Solein®. Its production pollutes 100 times less than beef and 10 times less than plants. And unlike conventional protein production, it takes just a fraction of water to produce. Since the protein can be produced anywhere - by the use of CO2 and electricity, Solar Foods is also decoupling food production from land use, to return arable land back to its natural state, which in turn will enable more natural carbon capture to take place.

Solar Foods sees their Solein® protein as only the beginning and the first product enabled by their technology.

“There is more to come,” said Pasi Vainikka, co-founder and CEO of Solar Foods, in an interview with The Org. “It is not only the current Solein that we can grow with electricity. We see it as an interesting platform technology.”

The company is an interdisciplinary spinout from the Finnish National Research Institute VTT and Lappeenranta University of Technology. Through combining research in renewable energy and bioprocess engineering, Solar Foods showcases how a multidisciplinary team may be needed for new scientific innovation.

“We are an example of these times in many respects,” said Vainikka. “One is that we are a classical example of a new solution that emerges from the intersection of scientific disciplines, rather than within a discipline.”

The team at Solar Foods consists of experts - or rather “artists” as Vainikka points out - from a multitude of disciplines. While aligned in their mission of creating a completely new food and building out a new platform technology, all artists are given freedom to follow their curiosity. “Then magic happens,” said Vainikka.

“Our story is reasoned by science,” said Vainikka. “We don't see ourselves as optimists or pessimists but rather possibilists.”

Vainikka attributes much of Solar Food’s initial innovation to how they were able to freely build a team without heavy organizational boundaries, which relates to aspects in the Scandinavian culture.

“No one is so highly held above others that you couldn't talk to them,” said Vainikka. “This is one of the Scandinavian specifics, we're not held back by our hierarchy.”

This autumn, Solar Foods closed their Series A financing round totalling €18.5M - making it the largest food-tech financing round in Finland to date.

“It shows that food tech is credible from the perspective of investors,” said Vainikka. “We are happy that food tech has reached this level, and hopefully there are many more companies to come.”

As they continue their growth and scientific explorations, Solar Foods hopes to inspire further innovation in food production and clean technology.

“We want to encourage others to try strange things.” said Vainikka.

Harnessing a 200-Million-Year-Old Invention

“We humans might be really good as engineers, we can develop incredible solutions, but nature is one of the biggest and most prominent engineers itself,” said Sofie Allert, co-founder & CEO of Swedish Algae Factory. “This is what really intrigued us when commercializing this material, we wanted to highlight what nature can do.”

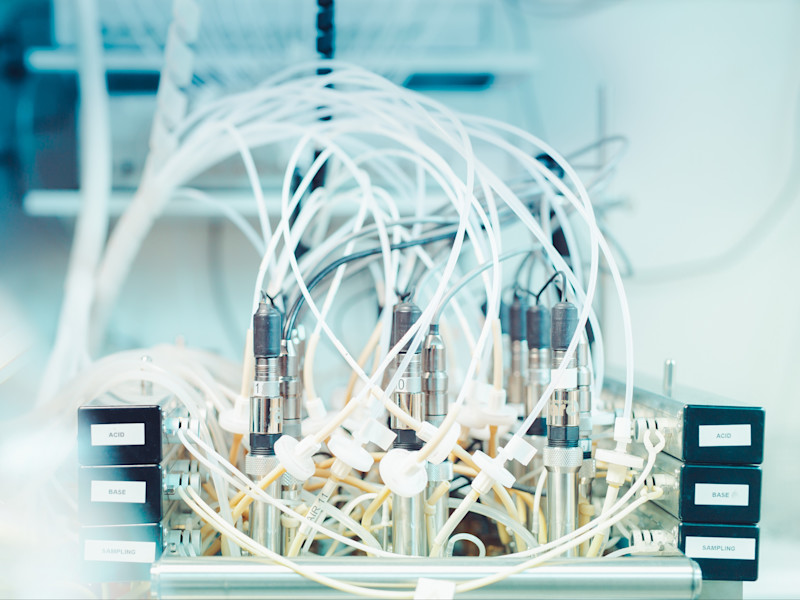

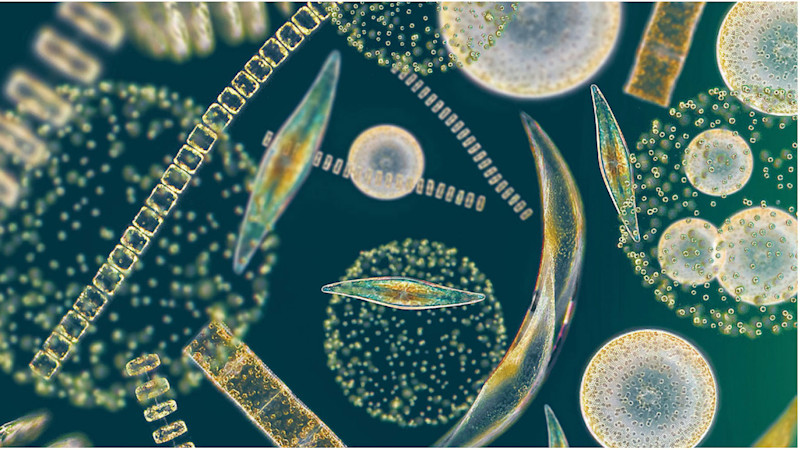

Swedish Algae Factory is extracting high-tech material from a rather untapped renewable resource: silica algae. The algae type, called diatoms, thrive in cold and dark climates and have existed for at least 200 million years. Throughout its evolution, the algae have developed unique light altering, absorptive and binding properties that are unmatched by synthetic materials.

“They have this really unique shell that is actually made of glass,” said Allert. “It has an incredibly beautiful and unique nano-porous structure that has been developed through evolution.”

The silica peel of the algae can replace harmful and less effective chemical substances in a variety of industrial products. And while this algae has been around long before human beings, the research on its properties and benefits is only at its very beginning.

Solar panels and personal care products are the first two markets Swedish Algae Factory are focusing on, together with continuous research building on the work of co-founder Angela Wulff.

Due to its unique light manipulation properties the algae material can be used to improve the efficiency of solar panels. For example, every kilo placed on solar panels causes at least 200 tons reduction in CO2 emissions through more solar power generation.

The material can also serve as a moisturizing, cleaning and UV protection in skincare products.

“National Geographic published an article last year where they show that 82,000 chemicals that are used in the personal care industry are actually harming our ocean,” said Allert. “It's an immense problem that we need to solve with better ingredients, since this industry is really prominent and really growing as well.”

To meet the current demand for their material in the personal care industry, Swedish Algae Factory is focused on scaling up production, and recently doubled their team from 6 to 11 people. The expansion was backed by a €4.77M investment round earlier this year with backing from both Swedish investors and the Dutch firm Aqua-Spark.

Since their founding in 2016, the Sweden-based company has focused on operating in harmony with nature. Their material’s production process is climate-positive, and based on a circular economy. During the cultivation in their factories, and through a controlled algae bloom, the algae traps at least 8x its weight in CO2, as well as nitrogen and phosphorus.

In the process, the company's algae factories are also used for environmentally friendly and low-cost wastewater treatment. Collaborating with fish farms, Swedish Algae Factory uses their nutritious wastewater as feed for their algae. The water is then returned back as clean and more oxygen rich to the farms.

“For us it's a way of thinking: How can you do good, instead of thinking how you can do a bit less bad? That’s how all industry needs to start to think,” said Allert.

From Waste to Value

*“Our vision is to get to a gigaton of carbon dioxide removal,” said Pia Henrietta Moon, co-founder & CEO of Carbo Culture. “Which is an insane goal, but it's the North star that guides our thinking.” *

Carbo Culture turns worthless woody waste from agriculture and forestry into high-value, functional biocarbon.

“Biocarbon is nothing new, charcoal is something people have made for thousands of years” said Moon. “What we have is a uniquely efficient conversion process, where we can trap more carbon than anybody else.”

Carbo Culture’s conversion process derives from a decade of research, and allows for an ultra-fast and environmentally beneficial carbon conversion. The biomaterial waste is quickly heated to over 700 C degrees, going from wood to a near-pure carbon that will last for over a 1000 years, meaning it won't decompose or re-enter the atmosphere. Through their process, the company both sequesters atmospheric CO2 and makes biocarbons, which in turn can be used as a functional material in urban environments and in bacterial processes. In this way, Carbo Culture sells both carbon removal credits - their physical removal of carbon from the atmosphere - and the actual biocarbon material.

Currently a small full-time team of four, with another ten part-time and supporting members, Carbo Culture is looking to double their mission-driven team in the coming year. Based in Finland and California - where they have their first demo scale facility - the startup has had feet on the ground in both places since the beginning, with both Nordic and U.S. investors.

“I think it's a great combination to be Finnish-Californian, there's a lot of similarities that we can use on either side of the pond,” said Moon. “It makes sense for an environmental company because California and Europe share a lot of similar traits. When it comes to environmentalism or environmental laws and regulations, California is the strictest in the U.S., and so it's a good match in that way.”

Carbo Culture wants to prove that large scale carbon drawdown can be profitable, scalable, and sustainable while delivering multiple systemic benefits.

“Our profits and the CO2 removal are totally aligned so that we don't have to choose which one we’re doing,” said Moon. “Every ton of material that we make sequesters carbon, and therefore the larger the profits the better it is for the planet.”

--

The Org is a professional community where transparent companies can show off their team to the world. Join your company here to add yourself to the org chart!

In this article

The ORG helps

you hire great

candidates

Free to use – try today